Industry-wide most standard ribbon blenders can typically handle bulk densities of around 35 lbscuft. Ribbon blender requires that the batch size the material volume in the vessel be equivalent to at least 30 to 40 percent of the blenders rated volumetric capacity.

The ability of this blender to handle solids of different size ranges bulk densities and other ingredient characteristics combined with the possibility of heating cooling drying and coating of solid particles makes its a very popular.

. For example if a blend comprises of 25 of ingredient A having bulk density of 500 kgm3 and 75 of ingredient B having bulk density of 1000 kgm3 the average bulk density should be calculated as follows. Average Bulk Density 025 x 500 075 x 1000 875 kgm3. Rec- ommended turndown ratio will be confirmed by the blender supplier.

Ribbons and support arms are clean and effi cient. Ribbon Blenders are also utilized for mixing discrete solid pieces within a low-viscosity liquid vehicle. High-quality ribbon blenders feature tightly controlled clearances between the trough surfaces and agitator tips.

Bearing mounted on lanterns out of mixing zone to avoid Cross. However process conditions such as impeller operation near a liquid surface can impose severe mechanical loads. The effects of fill height and blade rotation speed on mixing homogeneity have been studied.

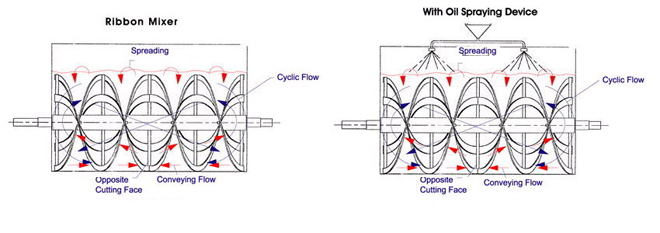

Due to their popularity and many uses ribbon blenders today are offered by many vendors big and small. The drive system includes fl exible belts and a set of pulleys to produce the desired speed and torque ranges. Working The outer ribbons of the agitator move the material from the ends to the center while the inner ribbons move the material from the center to ends.

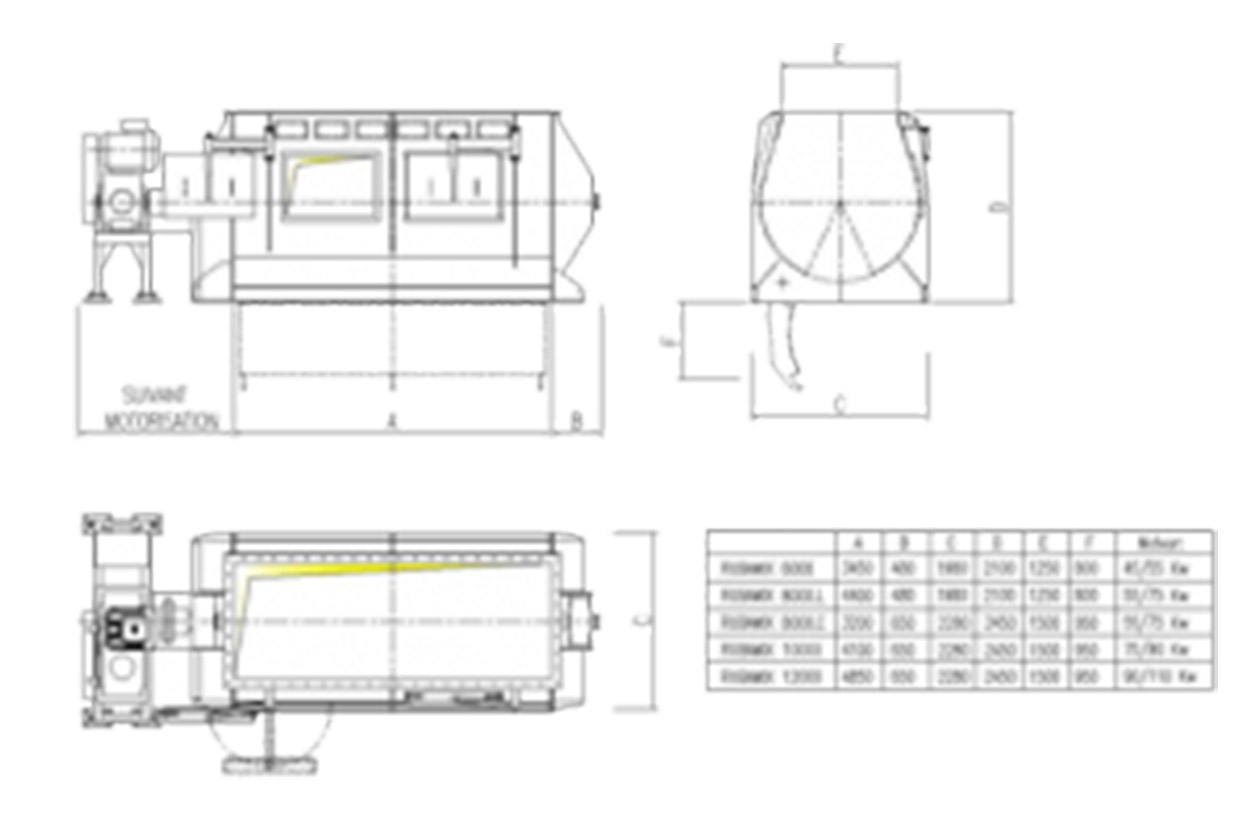

RIBBON BLENDER Mono block cGMP design SALIENT FEATURES. Usually a competent manufacturer of mixing equipment will take responsibility for the mechanical design. The desired batch volume determines the size of the blender but product bulk density determines if a standard or heavy-duty model is required.

The ribbon blender is one of the most versatile and commonly used blender in the chemical pharmaceutical and food industries. Optimal mixing in a. Capacity - 175 HP.

Equipped with a liquid-tight flush valve Ribbon Blenders built for this type of application can include jacketing around the trough to control product temperature. All contact parts in stainless steel 316. Froude number is comparing 2 forces.

Though mixer design begins with a focus on process requirements the mechanical design is essential for successful operation. W-for Large to Mega volume Capacity double shaft. Good design and expert fabrication ensure fast repeatable mixing easy clean-up low maintenance and long service life.

Design considerations had been studied during Analytical. More robust blenders are available for denser products. Ft 10 HPThis Ribbon Blender built in stainless steel and designed for center discharge is equipped with a control panel designed and built by Ross Systems Controls.

Fill your blender properly. Radial movement is achieved because of the rotational motion of the ribbons. All limit switches must be wired into the motor control circuit to disconnect power All stainless steel construction when the grates are removed or the covers opened depending on the blender design.

Drive design choices Traditional ribbon blenders utilize a belt drive for power transmission between the motor and gear reducer. Density -1600 kgm3 dia -1m lenght -2m material to mix - Dry cement mixing abt 2 tones please suggest me the power in hp. Froude number calculation for blender equipped with a mixing tool ribbon paddles With u tip speed mixing element D diameter of mixing element.

Batch size based on 65 of Blender volume. Fr forces other than gravity - mainly centrifugal gravity. If you are producing different blends in one blender Continued.

U-for Low to Medium volume Capacity single shaft. However some basic information and general rules may be sufficient to give direction for this designIn general these densities are at the moderately high end of powder properties handled in ribbon. The difference in the peripheral speeds of the outer and inner ribbons results in axial movement of the material along the horizontal.

To answer all of these questions with associated calculations is not a simple task since the mixer design involves many variables and design decisions. We have built nearly 50 of these stainless steel jacketed and internal pressure. Examples include ready-to-eat soups pasta sauces pet food and the like.

Available in two shapes - U W. Model 42N-515 Ribbon Blender 515 cu. Model 42N-25 Ribbon Blender 25 cu.

Performances of Dry solid powder mixing with in a twin Ribbon blade blender have been performed in this work in order to characterize mixing behavior in such a mixer of binary mixtures with different cohesionless materials.

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Mixing Performance Of Ribbon Mixers Effects Of Operational Parameters Sciencedirect

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender And Mixer Saintytec

Mixing Performance Of Ribbon Mixers Effects Of Operational Parameters Sciencedirect

Ribbon Blender Ribbon Mixer Ribbon Blender Expert Vortex Mixing Technology

0 comments

Post a Comment